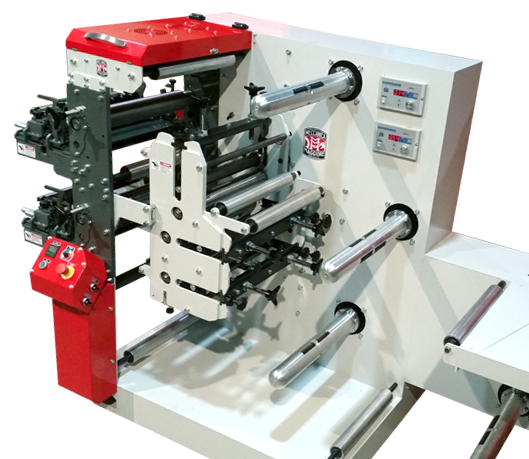

Excellent rotary die cutter with the possibility of installing up to 5 flexo units.

The MMP 250 and MMP 410 offer extensive operational efficiency and greater possibilities. It is a production machine, perfect for companies connected with the label production sector.

The MMP series facilitates the possibility to work with 720 mm diameter rolls, which constitutes to nearly 2000 running meters. Three rotary die cutting units (1 at the front, 1 at the bottom) enable manufacturing labels with black marks at the bottom, while simultaneously cutting out the desired shape, removing the waste and rewinding all in one pass. Supplementary printing units can be added, expanding the machine by 1,2,4 and 5 units that print in a stackable structure. The assemblage printing unit is based on a system of blades, which enable receiving a clear image. Moreover, it assists during the dismounting and cleaning process.

MMP 250 is not solely a label machine discover more possibilities!

A considerably thought-out construction, manufactured using the highest quality steel, guarantees a robust and durable performance for many decades. Our machines are designed by engineers and not by accountants, who would reduce the manufacturing costs by exploiting unreliable materials. However, this does not imply that the price of our machines is highly expensive – on the contrary- we are very competitive regarding our pricing policy, on the market. Power of simplicity – such an approach enables us to create machines, while excluding any expensive and often unreliable electronics, not making any concessions regarding productivity!

Our designers target is to provide a user-friendly machine, which works efficiently at a high-speed, is simple to operate, and will not limit the performance nonetheless, allows creating a wide range of products promptly and effortlessly.

MMP can be equipped with an automatic web guiding system, UV curing, sheeted cylinder, and slitting tools. Moreover, the machine is capable of winding media in two directions. Implementing one flexo unit will enable producing labels with a uniform color background, logos, texts, barcodes, or black marks on the bottom. For manufacturers, who use inkjet technology for label manufacturing, the device grants the possibility to independently apply the primer. An advanced and highly precise system of cutting and slitting blades, along with the knowledge necessary to operate them, opens new opportunities for greater working efficiency. It is possible to extend the machine up to 5 flexographic units, which allows printing CMYK in HD quality.

Set of special tooling for HD quality, incredible vivid colors and clear dots. 40% more quality when compared with other conventional flexo systems.

| SPECIFICATION: | MMP 250/ MMP 410 | ||||

|---|---|---|---|---|---|

|

|||||

| Cut system: | Flexible dies, Solid dies | ||||

| Cut stations: | 1 front 1 back | ||||

| Gear step: | CP 1/8″ | ||||

| Slitting tool: | static, 6 blades | ||||

| Max cut width: | 250 mm / 410 mm | ||||

| Max cut lenght: | 380 mm | ||||

| Max rewind diameter: | 2 x 500 mm | ||||

| Standard media shafts: | 3 x 76 mm, autoblock or mechanic | ||||

| Unwinder: | 1 (media) | ||||

| Rewinder:: | 1 media, 1 waste | ||||

| Max feed diameter: | 720 mm | ||||

| Meters counter: | Yes | ||||

| Magnetic cylinder: | No | ||||

| Printing unit: | 1, Flexographic, ceramic anilox, blade system | ||||

| Drying system: | IR | ||||

| Power: | 4.5 Kw, 380V, 3 fazy + zero | ||||

| Tension: | 50/60 Hz | ||||

| Dimensions: | MMP 250 – 106 x 180 x 100 cm | ||||

| Weight:: | MMP 250 – 480 kg | ||||

| Box size: | MMP 250 – 130 x 210 x 160 cm | ||||

| Delivery time: | 60 days | ||||