Simplicity is here!

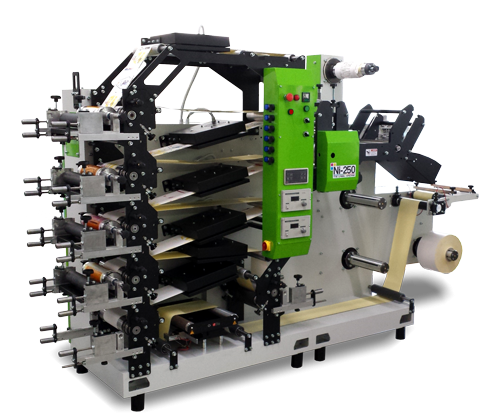

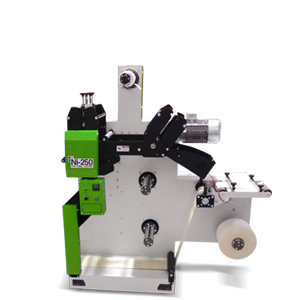

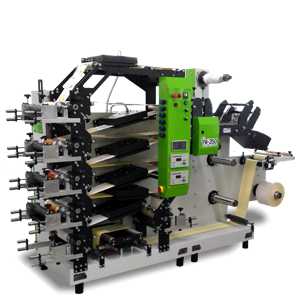

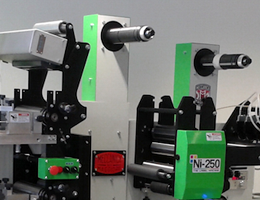

Ni 250 is a production class, unusually efficient flexographic printing system, intended for printing labels from roll to roll and from roll to sheet. A robust, rotary die equipped in 3 die cut units and 3 unwinding shafts are the basis of a system. Ni250 will enable you to transform your productivity to a higher level. Ni 250 is not solely about the commercial production of empty labels. A wide range of sophisticated products as well as specialistic knowledge regarding the manufacturing process, will prompt your company in becoming a leader in the industry.

We are here to customize a solution and create a machine tailored to your needs….

What are the main advantages of the Ni 250 system?

Manufactured, using the best European raw materials and components, which guarantee a reliable performance at minimal maintenance expenses for many decades. The machine is a perfect solution relative to high production of various roll to roll as well as roll to sheet products. In this version we can install the shaft unwinder along with the webguide on both sides of the machine. One, double-colored module enables printing labels with a logo or to apply different types of chemicals, and optionally glue. Thanks to an additional conveyor belt we can implement printing, cutting-out particular shapes, and the production of sheets from a roll, at high-speed in one pass.

Model overview:

| Specification: | Ni 250 complete | |

|---|---|---|

| the technical specyfication can be changed without previous warning. | ||

| Cut units: | 3 | |

| Gear step: | CP 1/8″ | |

| Max label length: | 450 mm | |

| Max label windth: | 250 mm | |

| Max speed: | 100 m/min | |

| Max unwind diam.: | 700 mm | |

| Max rewind diam.: | 450 mm | |

| Rewind shafts: | 3 pneumatic, 76 mm – 3″ | |

| Unwind shafts: | 1 pneumatic, 76 mm – 3″ | |

| Cluth/brake system | elecrtonic | |

| Split table: | yes | |

| Meter counter | yes | |

| Slitting device: | yes, 4 | |

| Page cointaner: | yes | |

| Power: | 380v, 4,5 Kw | |

About the printing unit….

Our goal was to design and build the most compact machine, without any compromise regarding the efficiency and printing quality. Owing to many years of experience, over many generations, we were able to accomplish exactly that. Knowledge connected with technological competency within the field of mechanical engineering, generated the development of the Ni250 series, which we can offer you today. This is a series of flexographic printing presses, which is unique in every aspect.

The Ni 250md and the NI 250tr were the fruit of designing machines while using a different approach. First of all, it is the highest possible HD print quality. Secondly, a simplified fast machine set-up time along with low material utilization. Thirdly, operational simplicity and color stability, consistent throughout the entire process and finally, you must see the machine in action, feel it by touching the machine, in the interest of acknowledging the quality of workmanship and see for one’s own eyes the quality of the final product.

We know that there are three main features, you must find in our products: the print quality, the appropriate machine capabilities and the competitive buying price. We firmly believe that our press machines are a turning breakthrough on the market and are changing a way of thinking regarding investment, the maintenance and operation of the roll-to-roll flexographic business.

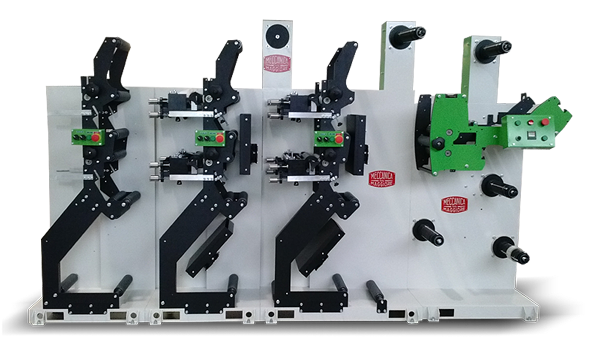

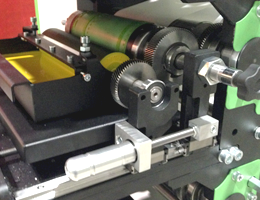

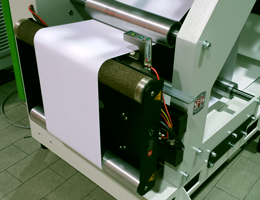

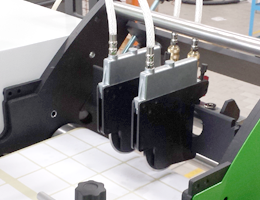

Printing unit

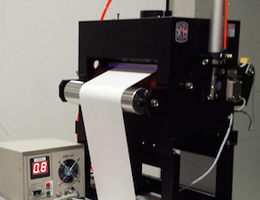

UV curing systems

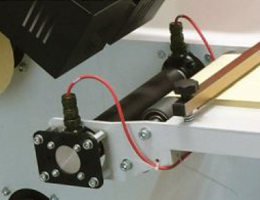

Auto alignment system

Cold-Foil unwind/rewind

Corona unit

Automatic tension control

Slitting tools